Circular Design 101 - part 4

The final post in my series: Circular Design 101 for Clothing - design to regenerate nature

Hey! Did you miss me? I know it’s about a two week late entry but things at Circular Sourcing have been ramping up to say the least as we prepare to pilot circulating surplus textiles with brands manufacturing offshore. (Meanwhile if you’re from a brand making offshore - I’d love to hear from you!)

PLUS. We launched two very exciting things last week.

There will be more to say on these great new tools, but in the meantime, I just couldn’t leave part 4 hanging like this for any longer! But hopefully it just means you’ve had time to catch up on the full series and thought of some great questions? My chat is open.

This is the fourth and final of this 101 series.

In case you need a little orientation, here’s where we are:

Part 1: Intro to Circular Design to regenerate nature

Part 2: Design products with knowledge, purpose and highest value

Part 3: Work within the constraints of a circular material strategy

Part 4: Create a plan for use cycles and end of life - we’re here, you did it!

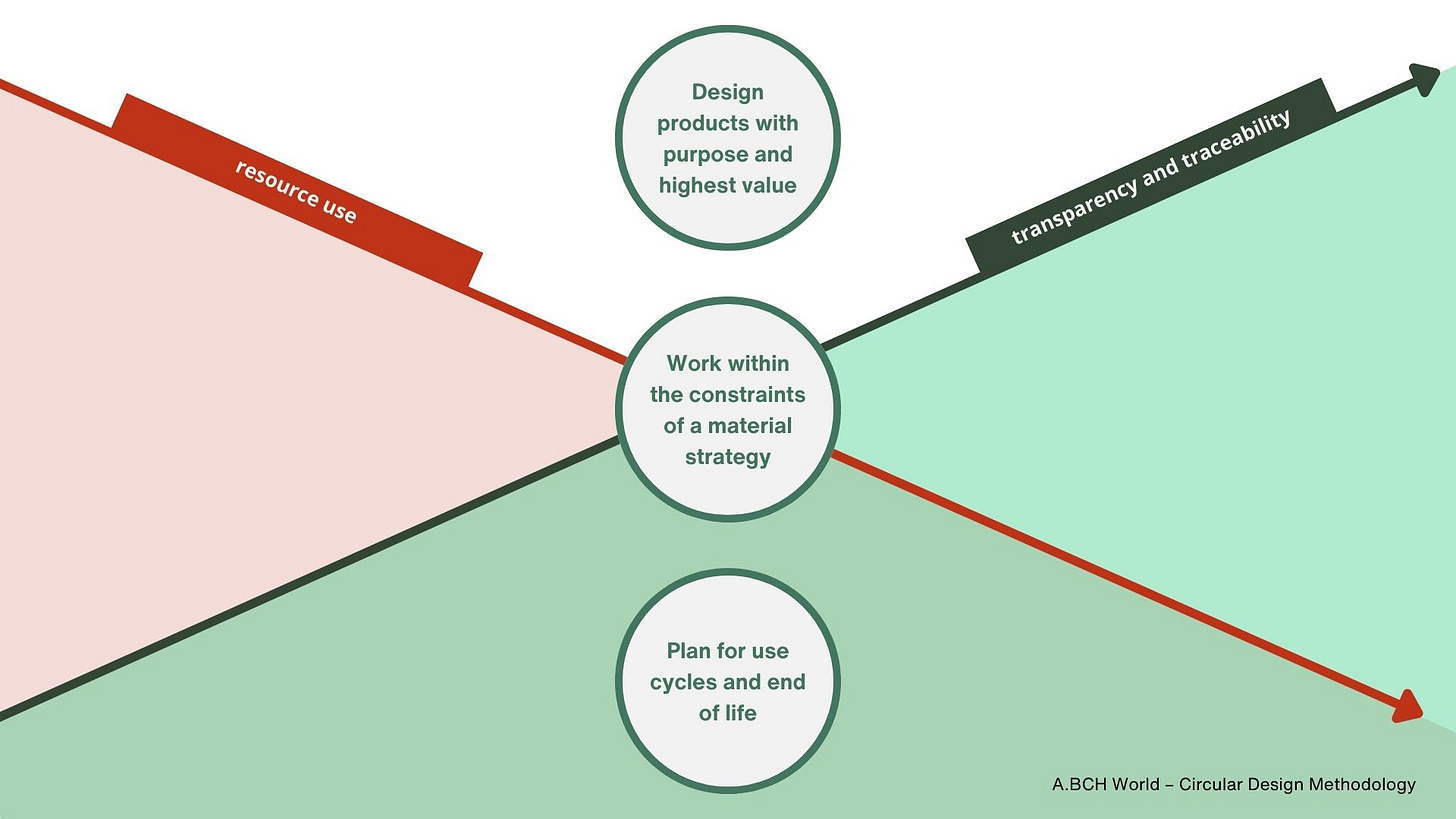

RECAP: Design to Regenerate Nature - my approach as a circular design practitioner

Product Design Actions:

Design products with knowledge, purpose and highest value

Work within the constraints of a circular material strategy

Create a plan for use cycles and end of life (at the design stage)

Ongoing Process Actions:

Increase the transparency and traceability of materials and products

Decrease resource use (eliminate use of virgin non-renewable resources)

Here’s a big picture view of these actions:

Today we land on Stage 3, if you missed Stage 1 or 2 or the Introduction, jump back to the links above to get the full story. Let’s get into it.

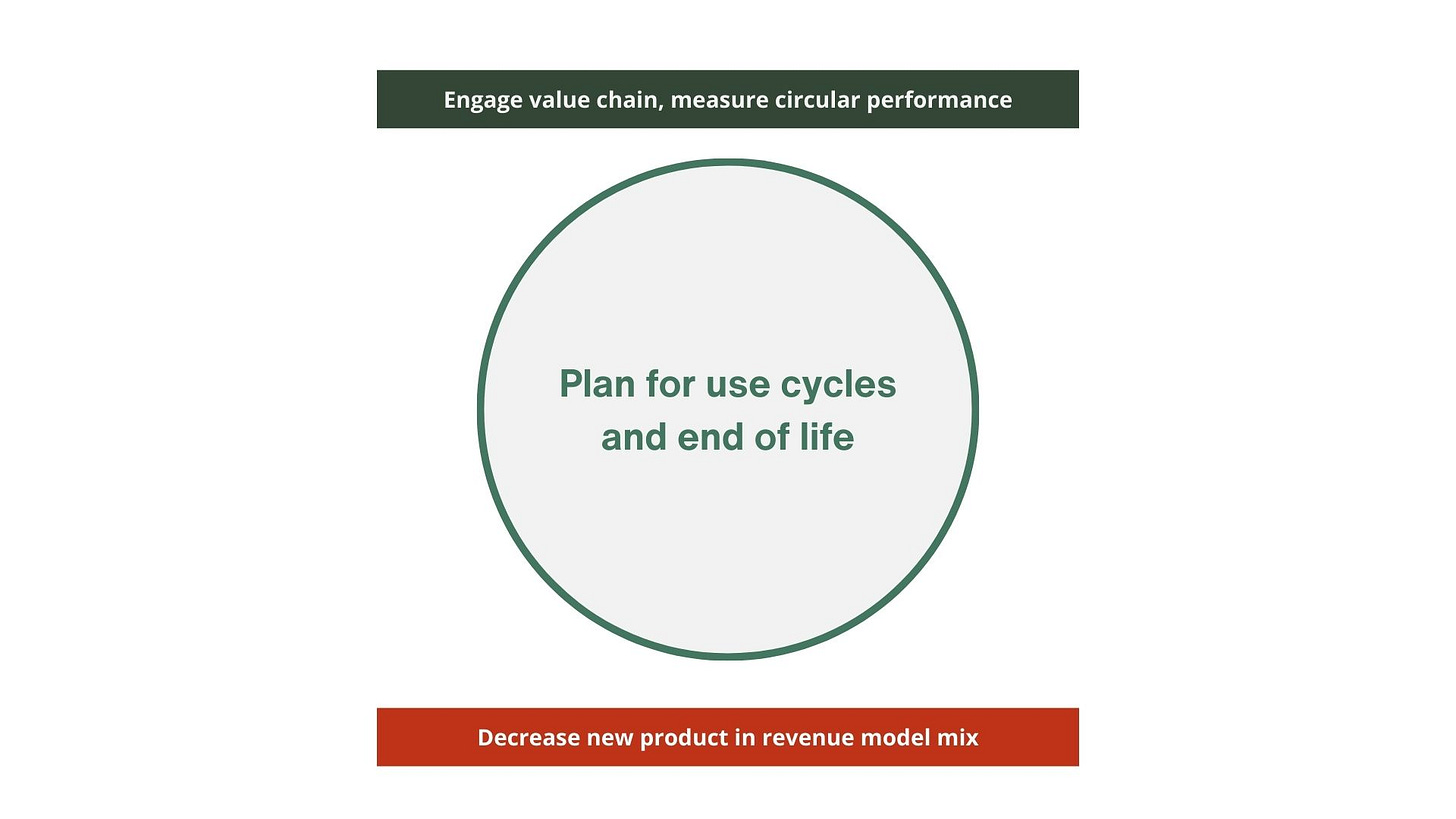

Stage 3: Plan for use cycles and end of life

Today I’m unpacking ‘Use Cycles’ and ‘End of Life’. What are they and why do we care, designers? My theory is, it’s during the design stage that we should consider, plan and communicate for the parts of the lifecycle previously thought to be none of our business! It includes after the customer takes your product home, or receives their parcel in the mail. It includes when the customer is done with the item and resells it or shares it with another. And it includes literally anything else that could or should happen to that item through repair, alteration, repurposing, or remanufacturing. These are the Use Cycles.

End of Life, on the other hand is not about the end of life of a product for a customer per se - it’s more about the product’s final destination. And really, there are only a few options available for clothes: think landfill, incineration, recycling or composting (in order of most to least popular). Anything else, like donating or repurposing all fall into the Use Cycles.

But Courtney! - you might be thinking. Are you really saying that if I want to design for circularity that I have to make plans and arrangements for my product’s lifecycle? Isn’t that totally out of my control?

Well yes, it is out of your control right now, but that’s because the customer or any other value chain provider (ie. repairer) is not accustomed to hearing from the producers about what to do with their products next. No plan in place means it’s anyones guess what should happen to these clothes, and as the quality of materials has deteriorated with the rise of fast, non-renewable textiles and clothing, so have the incentives to do meaningful work to preserve and reclaim new value from them.

We’ve created such low value monstrosities in modern clothing all the while increasing the amount of them far beyond what our generation or the next could ever need. What we are left with is horrible stuff that no-one particularly wants to extend the life of - nor is it a very appealing business opportunity for those of us working in the r-strategies.1

Something has to give and I think design is uniquely placed to be the first mover. Think about it, if we start designing better, more thoughtful stuff that people really love, and they come back to us as the responsible party for what to do next, we can influence a whole new culture of citizen behaviour. It won’t happen overnight, but if every good brand started to plan for their product’s life and communicated it well beyond the point of sale through whatever means necessary, like marketing and lifecycle programs - we could start to see some real momentum in circular action.

We’d need to have a pretty good system in place and ensure proper documentation is kept - just think about all the product going onto the market each day - and this would need to be standardised and accessible to parties who might handle your product after you. This is our increase action, where investment, upgraded systems and technology are needed to support the critical need for documentation at the design stage.

We’d also need to address the amount of product we put on the market that doesn’t fit in to a circular future - if you think back to the idea of Design Durability - how do we stop creating the stuff that isn’t meeting that criteria? How do we turn the tap off on the majority of product that loses its value so quickly, clogging landfills and overseas marketplaces? We must create a roadmap to move away from designing products that are ‘not yet circular’, especially when it is already possible to do so. Let’s reserve that title for products that are REALLY tricky due to specific performance needs (ie. firefighting uniforms) and work on those things longer term. So this is our decrease action, where non-design-durable products are eliminated, followed by an action plan to reduce and remove products that are ‘not yet circular’ from the market.

How does one create a Use Plan?

First it’s important to understand the Resource and Waste2 Hierarchy to see how our plan should naturally flow, as despite designing for highest value, it’s inevitable that a product will deteriorate over time.

I really like to refer to this diagram, whether I look at it from a consumer perspective, or from a designer’s - it’s just so useful to think through it.

Rethink, Reduce

In the hierarchy, we see Rethink and Reduce up the top - these speak to a designer’s action of Rethinking the product purpose (covered in part 2), and Reducing the materials that aren’t circular (covered in part 3). I hesitate to say a clothing designer should be reducing materials as a general rule at the individual product level (ie. product light-weighting) as I think a lot of the time in clothing, this can lead to a reduction in quality and longevity, and using less materials in a product does not always mean less waste. Of course there are exceptions, but we really must consider the product purpose and whether light-weighting an item will actually serve that or not.

Reuse, Repair

Then we get into the next section: Reuse and Repair. I like to think of these actions as the ‘High Cycles of Use’. Meaning a product stays as the product is intended and used in this high value form, making the most of the embodied impact to create it. Reuse (a catchall for any reusing action, whether it’s re-wear, resale, re-style, rental, swapping, sharing or donation) is the best first action, and of course when an item gets some wear and tear, Repair should be performed to return the product to its Reuse state and remember Reuse doesn’t always mean with a new user. High Cycles of Use are the best, highest value actions that you can design for and where a customer can claim highest value from. Pretty much all clothing should be designed for High Cycles of use, meaning the product team should actively think about, plan for, document and communicate the intended uses, including how they will communicate about repairs and implementing internal or external programs to keep product in use for as long as possible.

Remanufacture, Repurpose

Then we move down to the next section: Remanufacture and Repurpose. I think of these actions as the ‘Low Cycles of Use’ - simply because they are lower down on the Resource Hierarchy and because they require a destructive action to the original product form. The destructive action might indeed bring a whole new level of value to a product, however not without substantial effort. You might think of Remanufacturing or Upcycling, and the energy and efforts required to give a return on investment. Like a beautiful jacket make from an old quilt - the outcome can be stunning but not without a lot of work that leans into the artisanal rather than scalable. Repurposing or Downcycling on the other hand, generally requires lower effort (think a shredding machine or wiper rag cutting), but the final product value is much lower, and may even become contaminated with other materials or substances - thwarting its circularity potential in the end of life stage. Taking this a step further - not all products must flow to the Low Cycles of Use and the lifecycle plan should reflect this - it’s up to the product team to decide if this stage is truly necessary in their plan. If the product is ‘Not yet circular’ from a material strategy perspective (see part 3 in this series), then these should absolutely flow to the Low Cycles of Use.

Recycle, Recover

Down we go again into Recycle and then Recover (ie. waste to energy). We can think of human-made recycling like fibre to fibre recycling, or nature’s recycling through composting biological matter. In human-made recycling, there can be open loop recycling or closed loop recycling. To quote the newly launched Refashioning Circular Design Guide:

Recycling (Open Loop) is when products or disassembled materials are broken down to the fibre stage and are reprocessed into materials for a different end market to what the fibre originally came from. e.g., post consumer t-shirts recycled and processed into print paper. Note the difference between open loop recycling and repurposing.

Recycling (Closed Loop) is when products or disassembled materials are broken down to the fibre stage and reprocessed into yarns and materials of similar quality and function e.g., post consumer t-shirts recycled and processed into yarns for t-shirt fabric.

All circular products should be designed for an appropriate End of Life. And similar to the Use Plan, the product team should actively plan for the End of Life, detailing the decommissioning steps and the end of life pathway that makes the most sense from the circular material strategy (covered in part 3).

There really aren’t too many options here. The End of Life Pathways for clothing today are directly dictated by the circular material strategy and you can see in the diagram below what kind of products can go where.

The goal in planning this far ahead, regardless of whether or not your plan is followed is to enable circular systems. As things like the Digital Product Passport roll out, this will get easier and more streamlined for the customer, but we must start building the muscle today, not when DPPs become mandatory. If we want to move into circular systems then design has to move first, as the system is only enabled when the clothes are designed specifically to flow through them.

Anything else is truncated, sub-par and an after thought - treating value chain providers as waste collectors rather than partners who should be able to create or claim much higher value from the feedstock of clothing and textiles we see today.

Refashioning: Circular Systems - adapted from A.BCH World 2024

There is a lot more to share on how we actually implement all of this. I’d encourage you to check out the Refashioning Circular Design Guide, which goes into a lot more detail, as well as circular design software Quadrant Circular - launching later this month and linked right at the top of this post. These have been developed to help guide the fashion industry, to build a collective feedstock of simplified, quality materials for circularity to be realised. With less than 1% of clothing currently being recycled into new textiles, we see this as being a major obstacle to overcome, alongside everything else we know we need to do - citizen behaviour change, producing less, reducing toxic materials, pollution and non-renewables and getting real about recycling (ie. plastic rPET bottles should not be permitted to count as recycled polyester).

Regenerating Nature through and through

This is my final chance to bring it back to our theme - regenerating nature. Planning for the Use Cycle and End of Life are brilliant actions for regenerating nature as they require a total mindset change to design and use. In this series, the first two stages might have felt more within your domain of control, but when you start to think about taking full responsibility for the entire life and end of life of a product, it gives reason to pause.

Nature takes biological ingredients, digests them and returns value to an entire eco system along the way. As we often hear, there is no waste in nature. When we think about this, and apply this to the use phase of a garment, it forces us to rethink how our product is valued and how value is claimed and reclaimed through a system of interconnectedness. As much as I believe in design as a catalyst for change, we must decentralise ourselves as the hero of the story and instead empower the many lifecycle partners we will work with along the way to create a better world that more closely mimics the natural world.

When we think of where most clothing ends up (landfills - locally and abroad) it’s not hard to see we have become totally out of step with natural systems. Our consumption habits as individuals have been fully enabled by the system and businesses within it. So businesses must do the difficult work of designing and making circular product now, while empowering the customer behaviour change that we all must make. And as individuals, it’s up to us to accept the challenge of living happily with less, making much more out of what we have.

Final Words

As this is the final post in this series, I wanted to ask you what you think, what you learned and anything else you might like to share back. My plan it to share more, as I have endless ideas and thoughts on how to communicate circular design including an upcoming business series and a citizen series. Next I’ll be deep diving into Refashioning, sharing my experiences and maybe experimenting with some other mediums, like audio. If you have any thoughts on what you’d like to see (and how), I’d love to hear from you.

And finally, if you’ve enjoyed the Circular Design 101 series - please share it!

Thanks for reading,

Courtney Holm

R-Strategies are the actions conveniently beginning with the letter “r” that help extend a product or material’s life (ie. reuse, repair, remanufacture, repurpose etc etc)

I know the official title is the Resource and Waste Hierarchy or sometimes just the Waste Hierarchy - but I’m getting rid of waste as an option to force us to think about designing it out entirely and I am going to ignore it mostly in the breakdown/definitions.

Yes!!. Lets Build Up a 🌿Healthy ⚖️Balanced Economy For 🌏All

✋️Greetings From The Amazonia Networks in PERU😊👍👍🏽